Sustainability is a complex concept. It can be all too easy to lose sight of the simple idea that a sustainable business has minimal negative impact and bases its business model on solving sustainability challenges.

Circa is changing chemistry for good. Our business exists to enable the transition from fossil-based toxic chemicals that are used to manufacture countless every-day products. Solvents are ubiquitous in chemistry, yet for decades little has been done to improve upon these harmful materials, until now.

The EU Chemicals Strategy for Sustainability and the development of ‘safe and sustainable by design’ criteria by ECHA foreshadow the elimination of toxics solvents such as NMP and DMF. We are helping our customers to act on global regulations, such as REACH and TSCA, to minimise EHS risk and address growing drivers from their own customers for sustainably made products.

From purpose to practice

From its origins in 2006, Circa has had a clear set of criteria that apply sustainability to its production process.

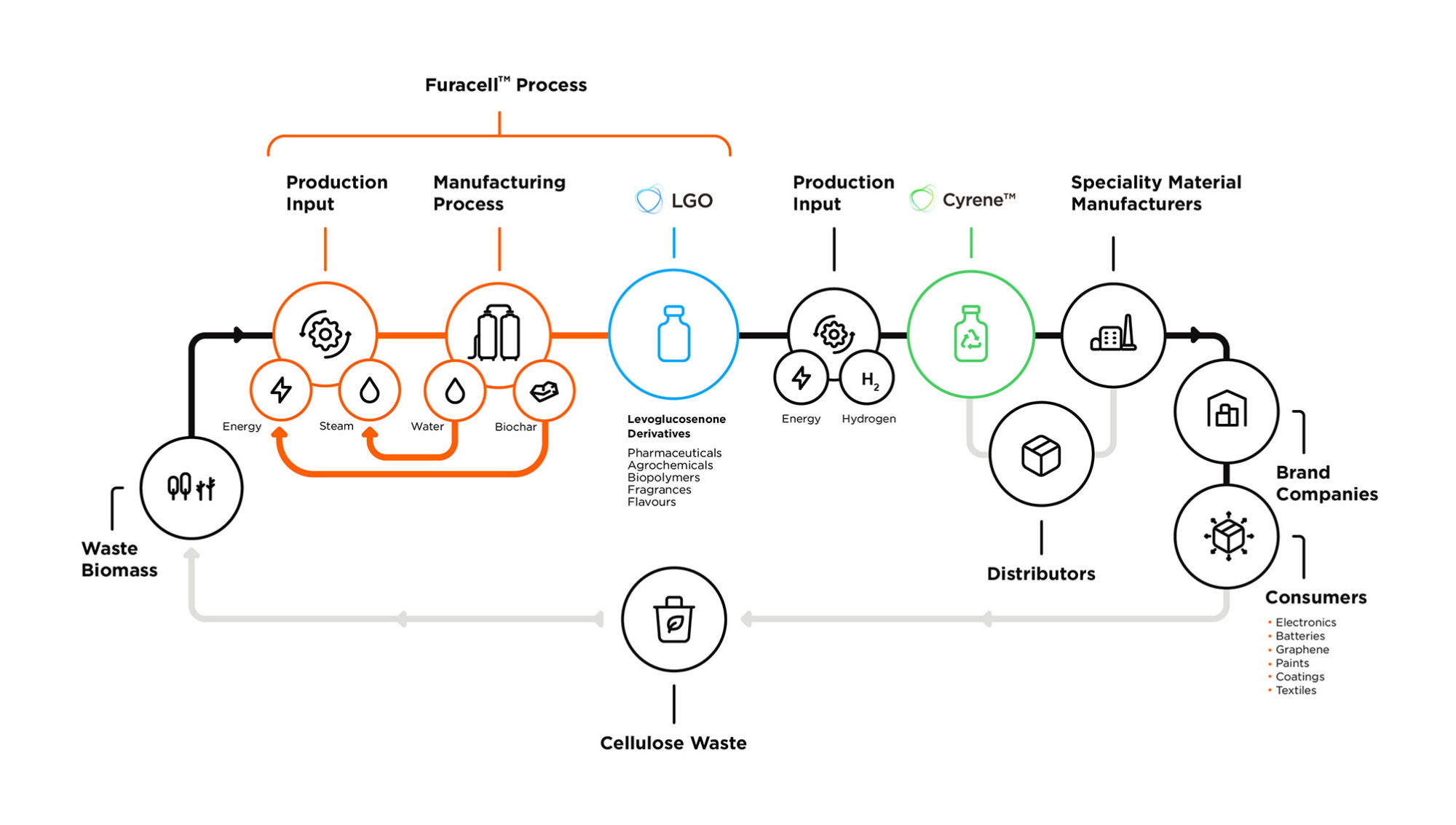

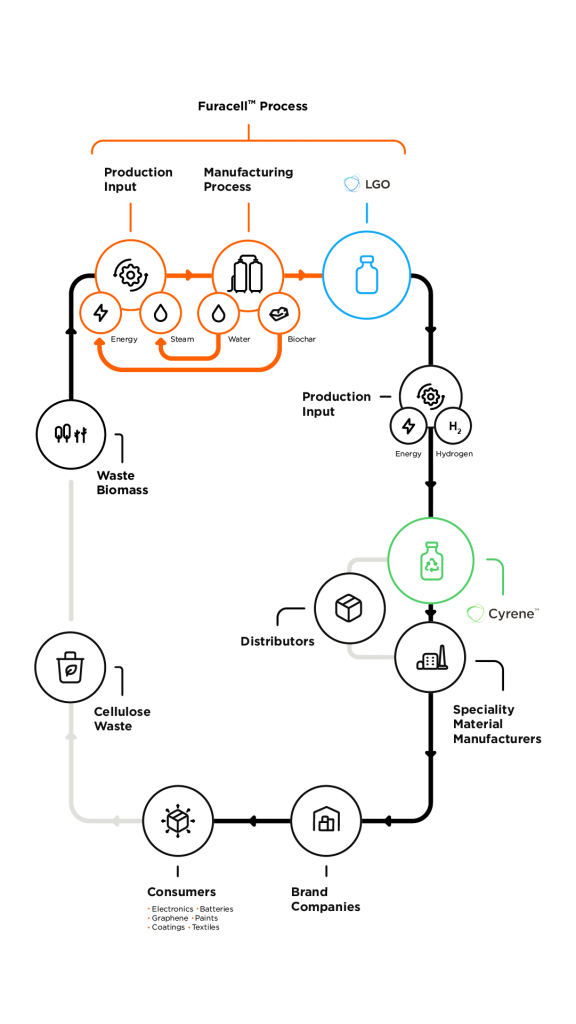

These principles led Circa to design its technology such that low toxicity, circularity and a minimal carbon footprint is a defining feature of the production process that results in LGO, the naturally occurring molecule from which our products are derived.

From this versatile building block, multiple sustainable bio-based chemicals can be developed to replace unsustainable fossil-based chemicals in a wide range of applications. Our bio-based solvent Cyrene™ derived from LGO, is greener, safer and performs better than traditional toxic solvents, which have been classified as substances of very high concern (SVHC).

The Furacell™ process has been designed to be:

Feedstock tolerant: a wide range of waste cellulose is suitable. We are not dependant on specific feedstock providers and the forest biomass we use makes beneficial use of waste from other industrial processes.

Carbon neutral: the production process is close to carbon neutral, with its feedstock coming from renewable carbon sources, and renewable energy sources used. Biochar produced by the process can fuel the Furacell™ process.

Environmentally benign: biochar and water are the two primary by-products. We can use the water created from the process as steam for process heat, and at end-of-life, Cyrene™ has no NOX or SOX avoiding the costly disposal strategies of other toxic solvents, such as NMP and DMF.

Circa values

Applying principles to product development is how we deliver on our purpose.

It is equally important that our organizational behaviours are values-based. Values form the foundation of our culture and guide how we do things at Circa. Our approach to people development establishes a shared understanding of our values and what they mean in the conduct of our business.

Courage

Initiative

Respect

Community

Accountability

Disclosure

Circa produces an annual report which describes the organizational strategy, our sustainability management approach and our ESG performance.